Just How a Galvo Scanner Boosts Laser Marking and Engraving

Just How a Galvo Scanner Boosts Laser Marking and Engraving

Blog Article

Discovering Various Usages of Galvo Scanners in Industrial and Medical Area

Galvo scanners, with their accuracy and speed, have come to be indispensable devices in both commercial and medical areas. Their applications vary from high-speed laser engraving and noting to precision cutting and welding, making them essential for decreasing product wastefulness and boosting quality assurance in production. In the clinical sector, these scanners significantly boost the precision of sensory surgical procedures and progressed imaging strategies, thus progressing person treatment. Yet, the full range of their capacities and the emerging developments they inspire continue to be a topic ripe for more exploration. What new frontiers do these versatile gadgets promise to unlock?

Laser Inscription and Marking

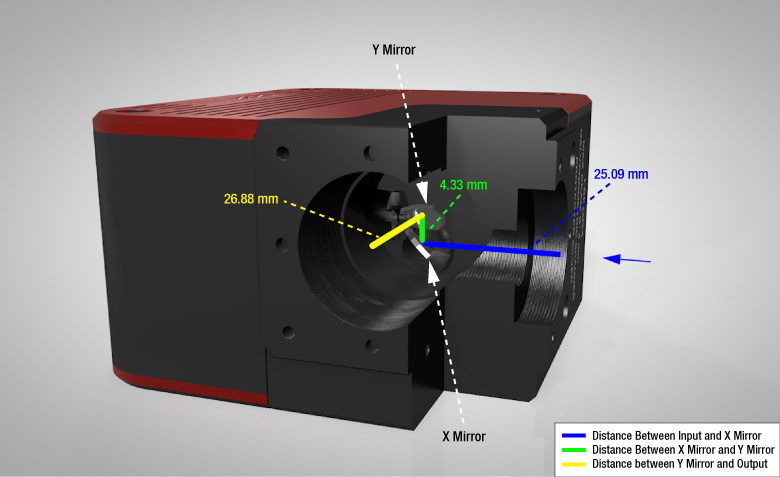

Laser marking and engraving, an essential application of galvo scanners, have actually revolutionized different markets by offering precision, rate, and adaptability. Galvo scanners, which make use of galvanometer-driven mirrors, overview laser beam of lights with impressive precision, allowing elaborate designs and text to be noted on a range of surface areas, such as metals, porcelains, and plastics. This modern technology is vital in markets varying from producing to clinical device manufacturing, where high-resolution marking is crucial for product branding, recognition, and traceability.

Furthermore, galvo-driven laser systems use unmatched adaptability. They can quickly adapt to various marking requirements, whether it's barcodes, QR codes, identification numbers, or complex logo designs. The accuracy and reliability of galvo scanners ensure constant quality, making them a recommended option for industries that demand rigid requirements, such as aerospace, electronics, and clinical tools.

Precision Reducing and Welding

In the world of accuracy cutting and welding, the abilities of galvo scanners have actually shown to be transformative. In commercial settings, galvo scanners are made use of to execute reducing operations on products varying from steels to polymers with unmatched precision.

Ophthalmic Surgical Applications

In LASIK surgery, the galvo scanner's high-speed mirrors direct the excimer laser to improve the cornea with exceptional precision, guaranteeing the corneal tissue is ablated consistently. This accuracy is crucial in attaining the desired refractive adjustment, improving the person's aesthetic skill. Similarly, in cataract surgical procedures, galvo scanners help with the precise fragmentation of the lens, enabling extra efficient elimination and decreasing the capacity for issues.

Furthermore, galvo scanners are crucial in retinal therapies, such browse around this site as photocoagulation for diabetic retinopathy. The determine precision of the laser delivery lessens damages to surrounding tissues, maintaining healthy and balanced retinal cells. In general, the unification of galvo scanners in ophthalmic surgical procedures represents a significant leap forward in medical precision and individual end results.

Advanced Medical Imaging

Beyond their substantial impact in ophthalmic surgical treatments, galvo scanners are additionally look at here now changing innovative medical imaging strategies. These tools are critical in improving the precision and speed of various imaging modalities, such as Optical Comprehensibility Tomography (OCT) and Confocal Microscopy. The rapid, accurate light beam steering provided by galvo scanners plays an essential duty in producing high-resolution pictures essential for very early medical diagnosis and treatment preparation.

In OCT, galvo scanners make it possible for the speedy scanning of tissue layers, helping with real-time, cross-sectional sights of biological frameworks. In Confocal Microscopy, galvo scanners improve the ability to get sharp, high-contrast pictures of mobile and subcellular frameworks.

In addition, galvo scanners contribute to the efficiency of fluoroscopy and endoscopy by enabling dynamic imaging of inner body organs with marginal invasiveness. Their integration right into these imaging systems makes sure reduced discomfort for people while offering medical professionals with trustworthy and comprehensive data, ultimately advancing patient treatment and results in clinical diagnostics.

Emerging Industrial Innovations

Galvo scanners go to the leading edge of arising industrial developments, changing a plethora of applications from manufacturing to quality assurance. In the realm of additive manufacturing, galvo scanners enable precise laser-based 3D printing, improving both speed and accuracy. This precision is essential for creating elaborate parts in aerospace, auto, and clinical device markets, where resistances are marginal and top quality is vital.

In addition, galvo scanners are crucial in boosting laser cutting and engraving procedures. By quickly guiding laser beam of lights with high accuracy, these gadgets can develop complex patterns and cuts in various products, consisting of metals, compounds, and plastics. This development not only minimizes manufacturing time but also decreases waste, leading to more sustainable manufacturing methods.

In quality assurance, galvo scanners facilitate non-contact evaluation and width. They enable fast, high-resolution scanning of elements to discover issues or discrepancies from design specs. This capacity is necessary for industries such as electronics and semiconductor production, where even minute imperfections can lead to substantial item failures.

Furthermore, the assimilation of galvo scanners in robot systems is transforming automated production line. By offering accurate placing and activity control, these scanners boost the performance and dependability of robotic operations, causing enhanced you could try here performance and minimized operational prices.

Final Thought

To conclude, galvo scanners show significant flexibility and accuracy in both medical and commercial applications. Their combination right into laser engraving, precision cutting, and welding processes boosts efficiency and high quality in manufacturing. In the clinical area, galvo scanners considerably enhance surgical outcomes and imaging methods, such as in ocular procedures and progressed imaging modern technologies. The ongoing advancement and adaptation of galvo scanners are critical in driving technological innovations across varied markets, highlighting their indispensable role in modern market and healthcare.

Galvo scanners, with their precision and speed, have actually become indispensable tools in both commercial and medical fields.Laser etching and marking, an essential application of galvo scanners, have revolutionized different markets by supplying convenience, rate, and accuracy. The precision and dependability of galvo scanners make certain consistent top quality, making them a favored selection for industries that require rigorous criteria, such as aerospace, electronics, and clinical devices.

In LASIK surgery, the galvo scanner's high-speed mirrors route the excimer laser to reshape the cornea with unequaled precision, making certain the corneal tissue is ablated consistently. galvo scanner.In verdict, galvo scanners demonstrate significant adaptability and precision in both industrial and medical applications

Report this page